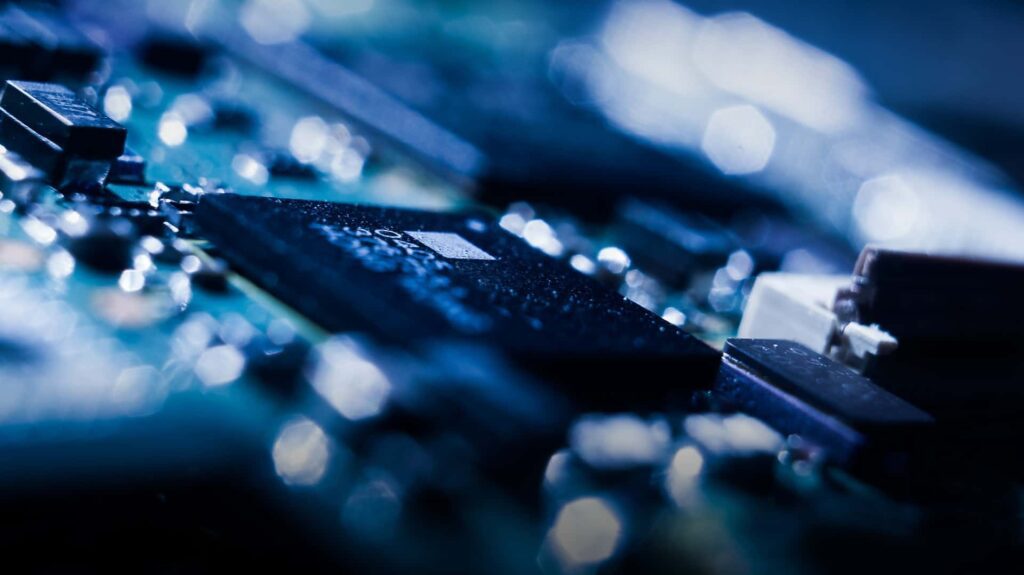

It started last year when gamers were unable to find graphic cards, Apple had to stagger the release of iPhone 12 and Xbox and PlayStation were unable to meet the demand for their latest consoles. The semiconductor chip shortage, or as one insider coined it, “Chipageddon” had arrived.

The 2021 chip shortage will be with us for the foreseeable future and will impact business technology.

How did the chip shortage happen?

It’s a classic combination of supply and demand.

The worldwide demand for semiconductor chips has been growing with the emergence of new technologies like 5G, cloud computing and artificial intelligence (AI). Chips are now in all kinds of devices like smart appliances, toys and games – if it has a battery or a plug, it probably has a chip.

One industry analyst estimates demand is 25% higher than anyone expected. According to the Semiconductor Industry Association (SIA), chips sales were up 13.2% in January 2021 from the same month a year ago.

Overlay this long-term structural trend with radical shifting in consumer and business buying patterns and you begin to see why shortages are popping up. For example, car sales dropped dramatically when the lockdown hit, and consumers began buying more consumer electronics like laptops, appliances and gaming consoles.

Consequently, car companies slowed production and chip manufacturers shifted their lines over to fulfill other industry demand. Then car sales rebounded strongly in the fall and shortages in that sector began to emerge.

That has been the industry dynamic across different verticals – competition for limited available supply. Which leads to the supply side of this equation.

Why can’t we make more chips?

First, we need to understand that the chip manufacturing process is complex and expensive. Adding capacity requires billions of dollars along with years of planning, construction and line optimization before a plant becomes operational, much less, profitable.

The industry has been underinvesting in recent years as it allowed demand to catch up with available capacity in order to maximize profitability. The large players like Intel and TSMC are making new investments, yet those plants are still a few years out from making a difference.

Secondly, chip manufacturing is concentrated in Asia – upwards to 80% of all production – primarily Taiwan, Korea and Japan. Only 12% is currently located in the US, one third of what it was back in the 90s. Intel and TSMC are adding capacity in Arizona as a part of their expansion plans.

Why does this matter?

It means the market is extremely susceptible to major disruptions due to political, economic and natural risks.

For example, the semiconductor manufacturing process requires large amounts of water. Taiwan is in the midst of a significant drought and has been shipping water to its major producers (e.g., TSMC). A Japanese plant suffered a large fire and the recent Texas snowstorms slowed production in Austin.

Add to those natural events, the US-China trade disputes. Huawei had stockpiled inventory in anticipation of US-China trade restrictions which further reduced available supply.

Cumulatively, these disruptions have created additional supply pressures in a capacity-constrained supply chain.

What does this mean for business technology availability?

Expert forecasts on how long shortages will be with us range anywhere from 3 months to 2 years. On average, one expert estimates, supply is currently about 20% below market demand in many affected industries.

Large technology companies and manufacturers will likely get preference due to their volume and market positions. And they will likely build inventory to ensure they have the inputs to meet their customers’ needs. That will mean less availability for smaller producers.

Be prepared to pay higher prices. When demand is greater than supply, paying more should expected. Prices will likely fluctuate. However, don’t wait for a deal next month if you know you’ll need something soon.

What can I do now to make sure we have the technology we need?

- Plan now for your future technology needs – if long-term demand is still growing and supply takes up to a few years to come online, don’t wait for supply/demand imbalance to get better any time soon.

- Order planned purchases now – laptops, servers, whatever has a chip in it that you know you’ll need. Be prepared for possible long lead times.

- Keep a buffer inventory of laptops and other tech gadgets – new employees can’t wait, equipment failures happen

- Move applications to the cloud – this is a longer-term strategy that requires planning with your IT partner, but the advantages go far beyond hardware availability.

- Buy used equipment – this can be risky but in an emergency situation it may be your only option. Here are several sites you can check out besides eBay and Amazon.

The chip logjam may be here for a while. So work with your IT vendor partners to make sure you understand their situation and expected lead times. And review your technology roadmap to know where you may be at risk of not achieving your planned goals given the current environment.

Fortune favors those best prepared.